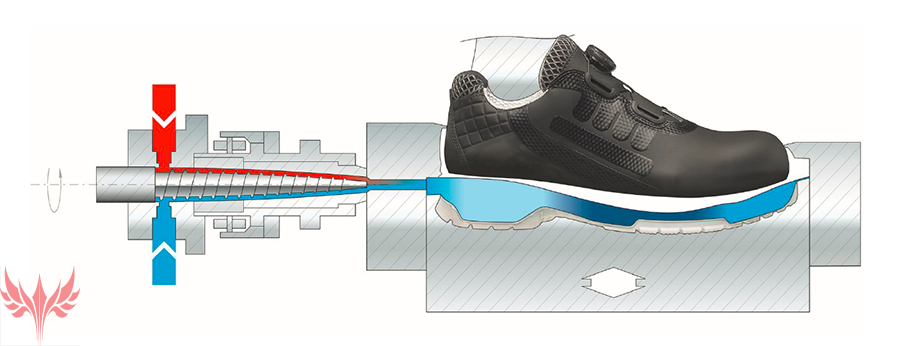

Direct Injection Process (DIP) PU

The PU, in liquid form is Injected into the closed mold (holding the upper) at high pressure. Thus we get the term “Direct Injection Moulding”. The PU hardens and permanently fuses into one piece with the upper. There is absolutely no chance of separation.

Sole Become integral Part of Upper

In case of Direct Injection Process, Sole becomes integral part of the upper, resulting in better bond strength as compared to other soling methods like Pouring, Stuck On etc.

Better Grain Structure of PU

Due to higher mixing speed of over 18000 rpm as compared to pouring method, better grain structure is obtained resulting into better physical and chemical properties.

Consistent Quality

Injection at high pressure into the close mould results in better flow of liquid into the mould that gives better results due to least atmospheric contact and self curing of mixed liquid.

Injection moulding machines used into the production of shoes are highly controlled machines in respect of temperature control, mixing pressure, mixing ratios etc. therefore better and consistent results are obtained.